|

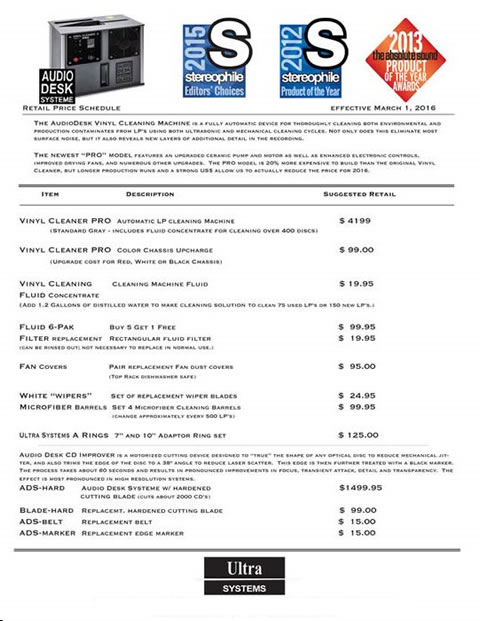

Audio Desk System Vinyl Cleaner

History of the Vinyl Cleaner

Development of the Vinyl Cleaner took designer Reiner Gläss four long years beginning in 2006. The first prototype, about 6 months in, was a somewhat primitive "brute force" ultrasonic machine, actually quite similar to a couple of ultrasonic-only cleaning machines which are currently being marketed for LP cleaning by other companies. But brute force and the LP don't mix well. Keep in mind that the bottom of the LP groove where the pointy diamond wants to track, can be less than a half micron in size, and the modulations within the groove are even smaller and more fragile.

And so began 3 more years of R&D to reduce the ultrasonic power which needed to be applied for safe and effective LP cleaning.

The addition of four counter-rotating microfiber-covered barrels as the primary means for the surface cleaning of fingerprints, etc., allowed for a significant reduction in ultrasonic wattage, and also serves an important fluid management function by wicking the ultrasonic agitation away from the LP surface into the cleaning solution where contaminants can be filtered. This fluid management is important because otherwise the contaminants the ultrasonic vibration removes from the surface of the record can simply redeposit back onto the LP surface.

Another improvement in cleaning efficiency allowing for a further reduction in the need for ultrasonic power was achieved through introduction of a cleaning solution surfactant to make the distilled water a better solvent when used in conjunction with the ultrasonic process.

Add a fluid filter to clean the re-circulating cleaning solution, and air filters to collect airborne dust which would otherwise be blown back onto the wet surface of the LP during the drying cycle, and you basically have the current machine - a record cleaning robot that cleans to the bottom of the groove, and then by using fan-assisted air drying, rather than static-inducing suction, leaves the user with a thoroughly cleaned record with no static charge attracting airborne dust.

Summary:

-safe low level ultrasonic to dislodge contaminants all the way to the bottom of the LP groove,

-bidirectional surface cleaning using microfiber-covered barrels, which also manages fluid motion to wick contaminants away from the LP surface,

-fluid filtration to remove contaminants,

-filtered air drying to avoid the introduction of a dust-attracting static charge to the LP surface,

-one button full automation.

|